The John Deere GT235, a model from the GT200 Series produced between 1999 and 2005, is known for its robustness and versatility. However, owners and potential buyers should be aware of its 5 common problems: engine starting difficulties, blade engagement issues, transmission randomness, uneven cutting, and steering challenges.

Digging into the quirks of this model is akin to navigating the British weather; unpredictable yet manageable with a bit of know-how. Luckily, Igra-World has done the heavy lifting for you, sifting through the mechanics and peculiarities of this tractor to keep your weekends free from unexpected tinkering.

Whether you’re considering the purchase of one of these models or you’re already the proud owner of one, understanding these issues is crucial. Knowledge about potential issues not only enhances the tractor’s performance and longevity but also saves you from unforeseen expenses and hassle.

- Engine Starts Hard: Mechanics like Carlos Hernandez from Miami often encounter hard-starting engines. The severity of this issue is medium. To fix this, test and replace worn-out spark plugs, adjust the carburetor as needed, and service the fuel system to clear any clogged fuel lines.

- Blade Engagement Issues: John, a seasoned dealer in Houston, frequently hears about blade engagement issues from buyers, rating the severity as low. The solution involves inspecting the PTO clutch for damage and replacing it if necessary, checking electrical connections to the PTO clutch, and adjusting the clutch if it’s out of alignment.

- Transmission Issues: Austin-based rancher Miguel Alvarez often discusses transmission issues he faces with the GT235, categorizing the severity as medium. Check for proper fluid levels and ensure the belts and pulleys are in good condition to address this.

- Uneven Cutting: Landscaping company owner Luis Martinez, operating in San Diego, regularly encounters uneven cutting issues, a problem of low severity. To resolve this, ensure the mower deck is level, blades are sharp, and the deck is free of debris.

- Difficulty Steering: Homeowner and tractor enthusiast Daniel Smith from Atlanta finds steering difficulties to be of low severity. Lubricating the steering system and checking for any worn or damaged parts can effectively fix this issue.

1. Engine Starts Hard

This lawn tractor can experience hard starts due to various issues, such as stale or contaminated fuel, a clogged fuel filter, faulty spark plugs, a clogged air filter, and carburetor malfunctions. Carlos Hernandez, a mechanic from Miami, frequently encounters this model with hard-starting engines. The severity of this issue is medium, and his approach includes testing and replacing worn-out spark plugs, adjusting the carburetor, and servicing the fuel system to clear any clogs.

Adding to this perspective, Riesterer & Schnell, a family-owned John Deere dealer in Wisconsin since 1931, emphasizes the importance of regular maintenance to prevent hard starts. They note that addressing these issues not only ensures smooth operation but also prolongs the life of the lawn tractor. Their experience with customers reveals that timely interventions can prevent more severe consequences later on.

How to Fix Engine Starts Hard:

- Inspect and Replace Fuel: Ensure the fuel is fresh and free from contamination. Replace with clean, fresh fuel if necessary.

- Check and Replace Spark Plugs: Inspect the spark plugs for wear. Replace with new ones, ensuring they are gapped to 0.028 inches (0.7mm) as per the specifications.

- Clean or Replace Air Filter: Make sure the air filter is clean to allow proper air flow to the engine. Replace if it’s dirty or clogged.

- Inspect and Clean Fuel Filter: Check the fuel filter for clogs and clean or replace as necessary to ensure fuel flows freely to the engine.

- Adjust the Carburetor: Adjust the carburetor to ensure the correct fuel-to-air ratio. Seek professional help if unsure about the adjustments.

- Service the Fuel System: Clear any clogged fuel lines and ensure the carburetor is functioning correctly.

- Check Ignition System: Inspect the ignition coil and other ignition system components for proper operation. Replace any worn out or defective parts to restore proper ignition.

2. Blade Engagement Issues

Blade engagement issues in these lawn tractors, such as those encountered by John, a seasoned dealer in Houston, are relatively common but usually of low severity. John frequently hears complaints about these issues, primarily stemming from the power take-off (PTO) clutch, drive belt, and electrical connections.

A misaligned or damaged PTO clutch can hinder proper blade engagement. Similarly, a worn or damaged drive belt and faulty electrical connections to the PTO clutch are significant contributors to these issues. Inspecting and possibly replacing the PTO clutch, checking and securing electrical connections, and ensuring the drive belt is in good condition are critical steps in addressing this.

From PrairieLand Partners, LLC in Winfield, Kansas, a licensed John Deere repair center, insights emphasize the importance of routine maintenance. “Regular check-ups and timely repairs of the PTO clutch and electrical systems can significantly reduce blade engagement hiccups, ensuring the longevity and reliability of your GT235,” they advise

This model’s specifications, such as its 18HP good ole fashioned Briggs & Stratton 570cc 2-cyl gasoline engine and electric PTO, are designed to provide reliable blade engagement during operation. However, any deviation in the mechanical or electrical integrity of these components can lead to crap failing. Battery health is also vital as a weak battery can hinder the electric clutch’s operation necessary for blade engagement.

How to Fix Blade Engagement Issues:

- Check the PTO switch: Ensure that the PTO switch is in the “on” position and functioning correctly. Replace it if necessary.

- Inspect the drive belt: Look for signs of wear or damage, replace the drive belt if needed.

- Check Electrical Connections: Ensure all electrical connections to the PTO clutch are secure and free from corrosion.

- Adjust or replace the PTO clutch: If the PTO clutch is out of alignment, adjust it. If it’s damaged, replace it.

- Inspect the battery: Ensure your battery is fully charged and in good condition as a weak battery can affect the electric clutch’s operation.

- Clean and Inspect the Mower Deck: Make sure the mower deck is clean and the blade is not hindered by debris or any other obstructions.

- Adjust Safety Switch Positions: Make sure all safety switches are in the correct positions to allow blade engagement.

- Consult a Professional: If you’re unable to resolve the issue, consult with a professional mechanic familiar with John Deere lawn tractors.

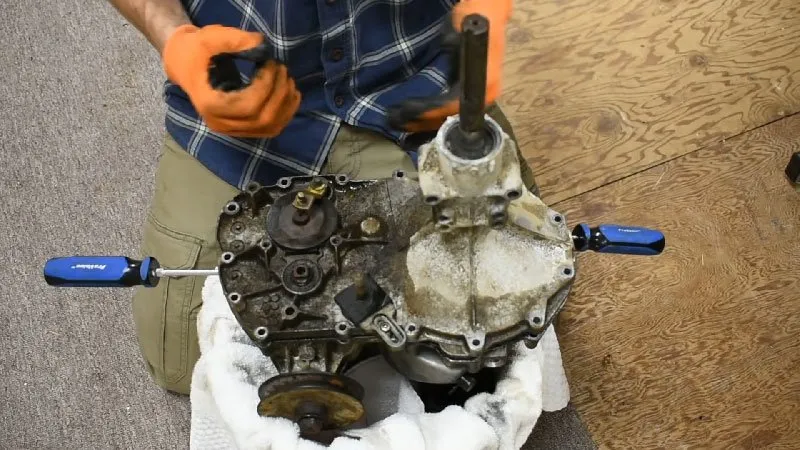

3. Transmission Issues

This popular among homeowners and professionals alike, faces several common transmission issues, especially as it ages. Austin-based rancher Miguel Alvarez has frequently discussed his experiences with transmission problems, categorizing their severity as medium.

These issues primarily stem from the tractor’s hydrostatic transmission system, which depends heavily on the right level and condition of transmission fluid. If this fluid level is too low or the fluid becomes contaminated, the tractor’s performance can suffer, leading to slow movement or even complete failure. Additionally, damaged or worn belts and pulleys connected to the transmission can cause further headaches.

At Martin Equipment, a John Deere dealership in Springfield, Illinois, technicians often encounter these transmission issues. They emphasize the importance of regular maintenance, stating, “Keeping the transmission fluid at the proper level and ensuring the belts and pulleys are in good condition are critical steps in preventing common transmission items from popping up. These issues, if left unaddressed, can lead to significant downtime and repair costs

How to Fix Transmission Issues:

- Check Transmission Fluid: Ensure the transmission fluid is at the correct level.

- Inspect Belts and Pulleys: Check the condition of the belts and pulleys connected to the transmission.

- Clean the Transmission Area: Remove any dirt, debris, or excessive dirt around the transmission area.

- Tighten Loose Bolts: Ensure all bolts are tightly secured, particularly those bolting the transmission to the frame.

- Check Linkages and Levers: Inspect the linkages and levers connected to the transmission for proper operation.

- Test Drive: After addressing the above steps, test drive the lawn tractor to see if the transmission issues have been resolved.

4. Uneven Cutting

Uneven cutting in the good ole’ GT235, as Luis Martinez, a landscaping company owner in San Diego, frequently encounters, can be attributed to several factors. Martinez notes that this low-severity issue often stems from a mower deck that isn’t level, dull blades, or a deck clogged with debris. Key causes include incorrect tire pressures, leading to an unlevel mower deck, and worn or damaged blades which fail to cut grass evenly. An unlevel deck and clogged mower deck further exacerbate this problem, along with damaged spindle bearings and inappropriate ground speed.

The technical aspects contributing to uneven cutting are diverse. Issues like incorrect tire pressure can unbalance the mower deck, while dull or damaged blades impact the cut quality. Ensuring the deck is level both side to side and front to back is crucial. Debris in the deck can obstruct blade movement, and damaged spindle bearings can cause uneven blade rotation. Additionally, too high a ground speed prevents adequate grass cutting.

Representatives at Martin Equipment, a female-owned John Deere dealership in Cedar Rapids, Iowa, stress the importance of regular maintenance for this model. “Proper care, including regular checks of blades and tire pressure, not only ensures a quality cut but also extends the life of the equipment,” they advise. Their extensive experience with John Deere products positions them as a reliable source for practical maintenance and troubleshooting advice

How to Fix Uneven Cutting:

- Check Tire Pressure: Ensure that all tires have the correct pressure as per the manufacturer’s specifications.

- Sharpen or Replace Blades: If the blades are dull or damaged, sharpen them or replace them with new ones.

- Level the Mower Deck: Ensure that the mower deck is level to the ground—adjust as necessary following the user manual guidelines.

- Clean the Mower Deck: Remove any grass clippings or debris that might be clogging the mower deck.

- Inspect Spindle Bearings: Check for any wear or damage in the spindle bearings and replace them if necessary.

- Check Ground Speed: Adjust your ground speed to ensure it’s not too fast for the conditions of the lawn you are mowing.

- Check the Power Take-off Clutch: Ensure the power take-off clutch is engaging the mower deck blades properly; adjust, repair, or replace if needed—this clutch is crucial for blade engagement and a smooth cut.

- Check Safety Switches Positions: Ensure the safety switches are in the correct positions; adjust or replace if it doesn’t help.

5. Difficulty Steering

Steering challenges in this John Deere , as experienced by homeowner and tractor enthusiast Daniel Smith from Atlanta, may vary in severity but are typically manageable. Smith suggests that regular lubrication and checking for worn or damaged parts are effective remedies. These steering issues, often arising from wear or misalignment in mechanical components like the sector, pinion, and drag link, or from worn tie rod ends, can significantly affect the tractor’s maneuverability.

From a technical standpoint, the steering system comprises essential elements such as the sector, pinion, drag link, and tie rod ends. Proper alignment and maintenance of these parts are critical for smooth operation. The tractor’s wet disc brakes also play a role in steering and handling.

Experts at Wilson Equipment in Salem, Oregon, a dealer specializing in similar equipment, emphasize the importance of regular maintenance to prevent such issues. “Proper care and timely replacement of steering components are key to maintaining this lawn mowers performance and avoiding more severe problems down the line,” they advise

How to Fix Difficulty Steering:

- Inspect for wear: Check the steering system for any worn or damaged parts, especially the tie rod ends and the steering arm ball joints.

- Check alignment: Ensure that the adjusters on the drag link are properly aligned to ensure smooth steering.

- Replace damaged parts: Replace any worn or damaged parts, such as the tie rod ends, to restore steering precision.

- Adjust the steering: Make necessary adjustments to the steering system to ensure it functions smoothly.

- Seek professional help if necessary: If you’re unable to resolve the steering issues, consider consulting a professional mechanic for further assistance.

If you don’t already own this model, should you buy it?

You should buy the GT235 because it’s a solid lawnmower, popular for both residential and commercial use, and even sought-after by collectors. However, it’s not without its flaws. Reviews mention occasional backfiring and a higher price point, but its functionality and versatility are praised. The most aggressive complaints focus on issues like engine performance and transmission, while simpler things like blade engagement and steering are relatively easy to manage.

Comparatively, models like the Cub Cadet XT1 LT50 or Husqvarna YTH18542 might offer fewer maintenance challenges or better value for certain users. The warranty for new John Deere equipment is provided in a separate document by the dealer, and it’s important to check how it covers these specific issues. Regarding repair costs, while specific dollar amounts are challenging to pinpoint, users should be prepared for potential expenses related to engine and transmission issues, which can be costly.

From the perspective of Dr. Emily Thompson, a pulmonologist in Bozeman, Montana, John Deere tractors, like other gas-powered lawn tractors, poses a risk of exhaust fume inhalation, and users should be mindful of ventilation when operating the machine to avoid health risks.

In conclusion, while this is a quality tractor, weigh its benefits against its potential problems and consider your specific needs and budget before making a decision.

Why trust Igra World?

At Igra World, the creation of our comprehensive troubleshooting guide for this GT-model wasn’t merely a desk job. Our seasoned mechanics dove hands-on into the common predicaments owners face—identifying, diagnosing, and investigating each hiccup this model is prone to. They spent arduous hours testing every solution, replacing parts, and adjusting mechanisms—ensuring the validity of our recommendations. Our editors, with grease-still-under-their-fingernails, pored over the feedback from actual GT2XX users, further refining the guide. We consulted extensively with other professionals in the field—repairing more complex issues under their guidance.

Despite the robust build of this tractor, our findings brought to light an array of issues such as engine overheating, electrical system malfunctions, transmission slipping, and mower deck engagement. The guide encapsulates a reality-checked maintenance regimen ensuring your John Deere doesn’t just occupy your garage but masters your lawn. Our thorough approach, blending real-world experience with technical expertise, makes Igra World’s troubleshooting guide an indispensable companion for every owner of this model.

Our assessment? While a sturdy piece of machinery, has its share of flaws that demand attention—reflecting a sentiment echoed by many in our community. Through this rigorous process, we’ve unearthed not just solutions, but a roadmap for what to expect—and what to inspect—in your journey.